There are many like it but this one is mine. My long standing meaningful relationship of almost 20 years with my Porter Cable saw finally ended when it could no longer meet my emotional needs. I needed a reliable, accurate, and moveable saw. It wanted to quit, or die. We just wanted different things in life or I just wanted a new saw. I forget which. So…after months of research, the Princess authorized a new saw, more than likely to get me to quit moaning about saws.

In my global search to all corners of the planet I considered numerous brands and levels of quality. I also learned that there are actually only a few manufacturers of table saws, most of which are in China. Initially, I tried to do the cost/benefit comparison and had a trial run with a Grizzly saw on the premise that I probably won’t live forever. But, my experience was dismal and the logic came down to “buy once, cry once”. This put me in the market for Saw Stop, Powermatic, and Harvey. I rejected the Saw Stop because I inadvertently cut enough nails and screws to know I’d be heavily invested in brake cartridges. New Powermatic owners seemed less than thrilled at a high price-point. And I like the high quality narrative (“Good enough is not enough.) that comes with Harvey.

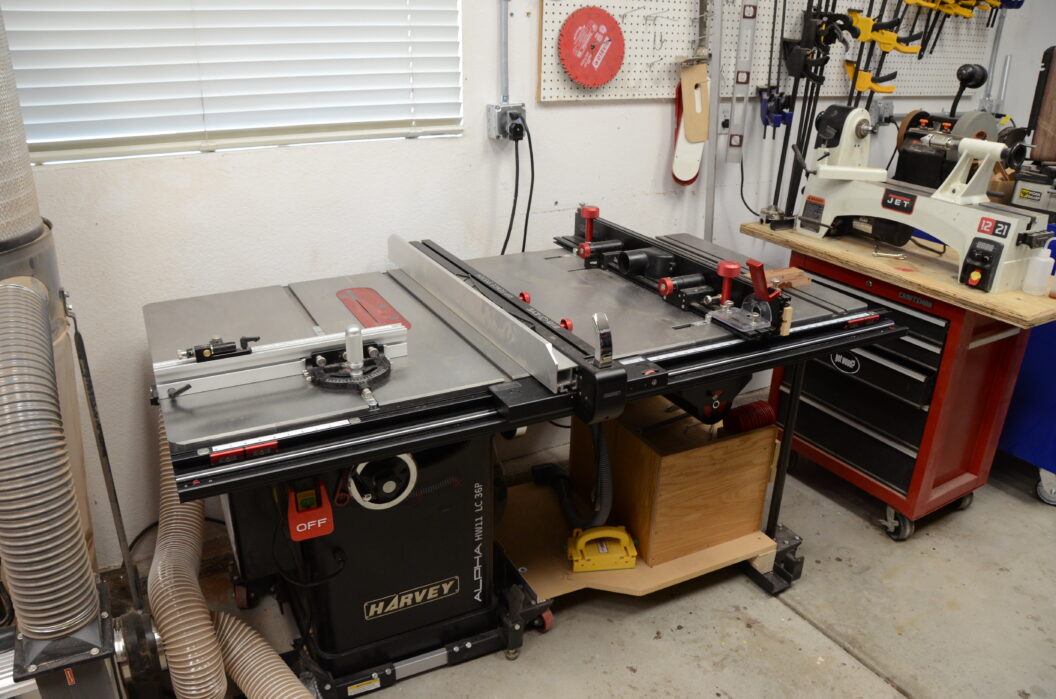

I bought the Harvey for several reasons and one of them was the HP for 110v in the range of saws I was looking at. My “Lumber Jocks” mentor Dave rejects my logic but at my age and attitude, I just couldn’t see upgrading my micro shop to 220 volts to get more powerful tools. And…for 90% of what I do, the saw is more than powerful enough. Anyway, I selected the Alpha HW11 LC 36P. High on my required criteria was the cast iron trunion, cast iron work surface with extensions, and…I could add the cast iron router table to it (which I did).

But, if you go down this road, know that it’s expensive (really) and frustrating. Harvey’s marketing model has an almost daily price and shipping change. Don’t like the price, wait 24 hours. Moreover, they charge a flat fee for shipping which meant that for being less than 500 miles from their warehouse I paid the same amount as the guy in Florida would. Secondly, I didn’t need the included miter gauge and the Harvey sales representative was glad not to ship it but it wouldn’t change the price of the saw.

So, I placed my order and started waiting. In the meantime, I stupidly checked the price of the saw I bought and watched it go down over $100, then back up, then $150 down, etc. I couldn’t help but feel I’d made a bad decision. But then the saw arrived on it’s pallet and all was forgiven…for the moment.

Harvey did an excellent job packing the saw and accessories. It comes cocooned in cardboard and bolted to the wood pallet it ships on. Carefully peeling away the recyclables was almost an hour of work but there was neither a mark nor a flaw in the saw. I had already purchased a heavy duty Bora mobile base and with some careful scheming, the Princess and I wrangled the cabinet off the pallet and onto the mobile base without too much cussing and zero crushed fingers. Know that this beast is heavy!

Once on the rollers, the rest was easy, except for disposing of the mountain of cardboard and pallet. Two things did not go well…the first was that I had failed to read the details on the plug the saw uses. It uses a NEMA 5-20P 20 amp plug which has one blade at 90 degrees to the other. So…no plugging it in until I got that sorted. The second was the lack of shims for achieving coplanar of the working surfaces. The Harvey solution is to use tape between the table sections and trial fit repeatedly until you get level. For the price of this beast, some brass or steel shims would have been helpful. As it was, this senior citizen managed to hoist the 80lbs sections up and down until I got the surfaces flat. Over the last year, I’ve had to adjust this a few times as the tape got old and compressed.

There were quite a few things that could have been better. The instructions are not as clear as they should be, the fasteners are not high quality or uniform in size, and some of their selections just made assembly harder (like socket bolts instead of hex bolts). I eventually bought grade 8 hardware and replaced all the table assembly bolts with hex bolts. After assembly, the rest was just tuning adjustments until the blade was square to the table, the fence ran smoothly (really smoothly!) and was square to the blade. I used a Woodpeckers saw gauge to do this and I highly recommend this tool. The manual explains how to adjust the different assemblies bit not why. For a comprehensive walk-through of the processes and why you need to do them, it’d be hard to do better than this YouTube video at “The Shack.”

So, all the complaining aside, this saw is…excellent. Even before upgrading to a “Big Eye” fence, accuracy was far above anything I had used before, including a commercial Powermatic with a Besimeyer fence. Everything runs smoothly and the adjustments to saw angle and lift etc are precise and repeatable.

Some modifications and notes:

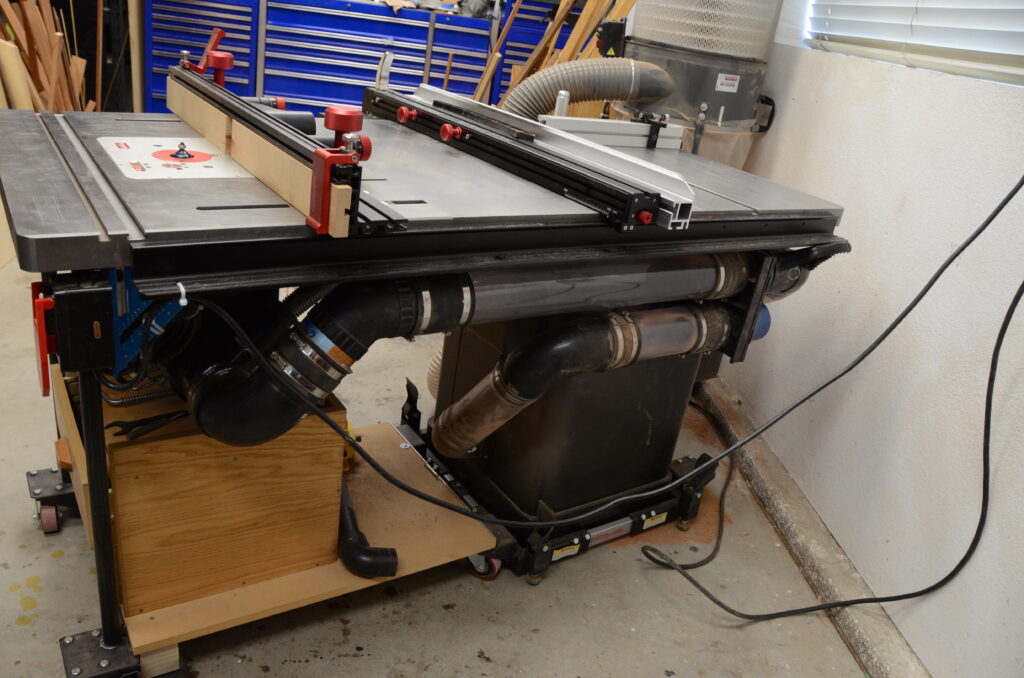

- I opted not to use the Harvey blade guard and dust control. The bottom of the saw is open and anything under the blade that doesn’t get sucked up falls to the floor. Above the table, I use a shop vac in between major cuts. I modified the dust control port to bypass the Harvey overhead connection and hard-piped the dust control to the back of the saw (along with a manifold for the router table). Because I use zero clearance inserts (see below), there’s a lot of crap on the floor after a large project.

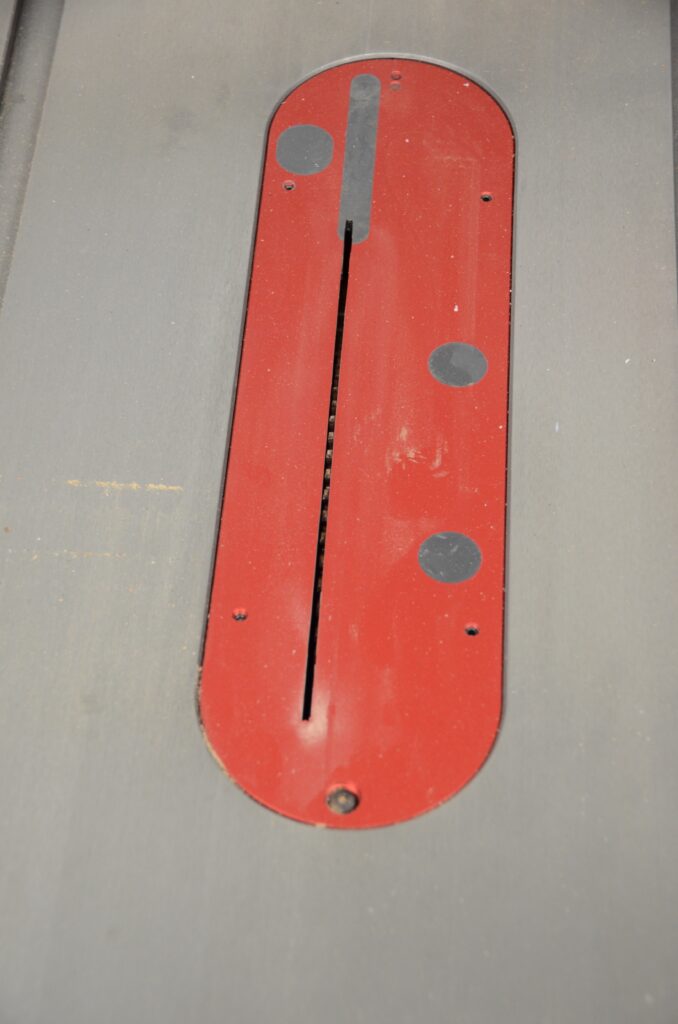

- I use zero clearance inserts almost all the time. The inserts that come with the saw are aluminum and are things of beauty. But…there are a lot of extra holes for the riving knife, finger cutouts, etc. I filled in the Harvey zero insert with epoxy which worked pretty well but know that a replacement insert from Harvey was over $80. After some experimentation, I found that phenolic resin zero clearance inserts for a Powermatic 66 work pretty well. You can find them on Amazon and Etsy. They need some additional screws installed to make it tight and there are no hold down screw holes but this is easily remedied. Care is required when cutting these though as the blade section is lower than the lowest position of the blade, meaning that the raw insert will ride on the blade above the table. Avoid this by installing an 8″ blade on the saw for the initial cut. Then switch to the 10″ blade to finish the cut. I’ve cut inserts for a standard kerf and a thin kerf blade and none of my small parts fall through the throat.

- This saw table sits lower than a lot of other saws. Consequently, a big project may wear your back out. My Lumberjocks buddy Dave, made a platform on casters that’s approximately four inches higher and I think that may be the answer. This will also close off the base of the saw so you’ll need to check your dust control as well.

- The add-on router table does not have the same edge profile as the saw; it has a different beveled edge. If you use tools that ride on the edge of the table (like large squares) this may change your workflow.

- The OEM power cord is a bit short for my shop so I made a longer one.

- While I think the Harvey products are top quality, their customer service and policies leave a lot to be desired. I tend to be pretty “brand loyal”, especially with expensive toys, but after my experience with the “Big Eye”, I won’t be buying another Harvey product.